VAT PASTE

VAT PASTE

Vat paste is a type of dyeing material that is commonly used in textile dyeing. It is a concentrated form of vat dye, which is a type of dye that is soluble in reducing agents such as sodium hydrosulfite or thiourea dioxide. Vat dyes are known for their excellent colorfastness and resistance to fading, and are commonly used to dye cotton, linen, and other cellulose fibers. Vat paste is a thick, viscous substance that is made by mixing the vat dye with a carrier material such as starch, gum, or synthetic thickeners. This mixture is then dried and ground into a fine powder. The resulting powder can be easily dissolved in water to create a paste that can be used in textile dyeing. Vat paste is preferred over liquid vat dyes in many applications due to its ease of handling and better penetration properties. It is commonly used in dyeing large batches of fabric and in industrial textile applications.

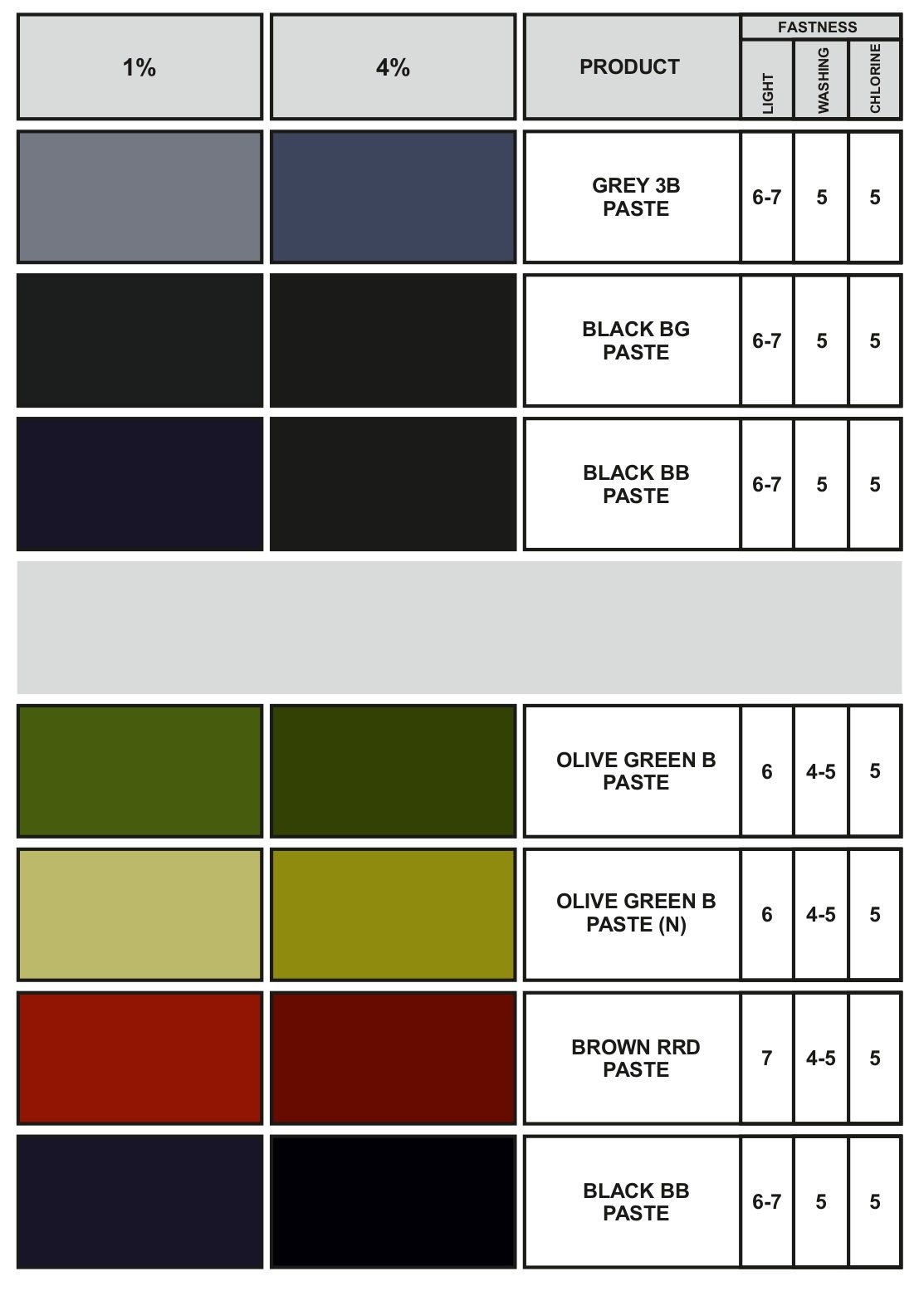

This Pattern Card illustrates range of Vat Dyestuff Indigoid & Anthraquinonoid Vats in Micro dispersed (MD) paste form suitable for textile printing on cellulosic fabric like cotton, Rayon viscose staple, cuprammonium Rayon etc. & also discharge print on dischargeable dyed cellulosic fabrics.

The particle of dyestuff in this range have been brought down to extremely small size & they have been transformed into a fine dispersion with the help of most modern technique giving considerable stability and uniformity to the paste and facilities easy fixation of dyestuffs even under varyingcondition of steaming.

(MD) Vat Paste have excellent brightness, dispersion and all fastness properties and cover complete range of colors from Yellow to Black.

Quality Control

150 Gms Rangolite C Powder

120 Gms Potassium Carbonate

50 Gms Glycerin

680 Gms Thickener

1000 Gms

For Black BG Paste Extra addition of Potassium carbonate

Straining

Printing paste prepared above is filtered through a fine cloth before printing in order to remove hard particles from the Paste.

Drying & Steaming

Printed cloth should be dried well at 50° 55° C. Steaming is carried out continuously in a Rapid ager for 10-12 mins or in Star ager (20-25 min) with moist steam at 101°C-103°C (under pressure) and in absence of air.

Oxidation

The steamed fabric is oxidized to convert Leuco compound formed during steaming into insoluble VAT color which is fixed on the fabric.

The Steamed fabric is oxidized by treating in a bath containing

2-3 gm/lit Sodium perborate OR

2-3 gm/lit Hydrogen peroxide with

0.5-1CC/lit Glacial Acetic Acid at 40°-45° C

temp for 5-10 min. to keep the steamed before chemical oxidation

Soaping

After Oxidation fabrics are rinsed well and soaped at boil with 3 gm/lit. Soap &2 gm/lit. Soda Ash. For viscous fabric soaping is carried out at 80°C. Wash & dry for getting brilliant & excellent shades of Micro Dispersed Paste.

Important Points (To Be Followed)

Following points of useful information are given in connection of Vat Paste.

i) For best results scouring and bleaching of fabrics is important.

ABOUT US

Pink Lotus Chemical Industries is a leading manufacturer and exporter of Pigment Emulsions, Vat Paste, Fluorescent Paste, Pigment Powder, Vat Powder & Textile Auxiliaries in India under the brand name of “ECO-CRON”.

OUR PRODUCTS

SOCIAL LINKS

CONTACT US

Address

- 22, Sarjan Industrial Estate, Ambica Tube Compound, Near Vatva Over Bridge, Vatva, Ahmedabad, Gujarat, India - 382445